How To Guides

- How to undertake a professional quality repair of your PVC or Hypalon RIB, inflatable boat and SIB tubes

- How to clean inflatable boats, protect RIB collars, tubes and sponsons, clean Hypalon and PVC inflatable boat fabric

- How to find a leak in my inflatable boat, RIB, dinghy, life raft or inflatable kayak collar or tubes

- How to fit a replacement screw-in type inflatable boat, rigid inflatable boat (RIB) or dinghy inflation deflation valve

- How to fix or glue inflatable boat PVC fabric patches and accessories to Hypalon fabric RIB collars and tubes (and vice versa)

- How to identify the fabric of your RIB, inflatable boat, dinghy, life raft or inflatable kayak collar, tube or sponson. Hypalon or PVC?

- How to repair inflatable boat, RIB, RHIB, SIB and kayak collars, inflation tubes or sponsons

- How to replace a Leafield Marine A4 inflation/deflation valve older inflatable boats, RIBs, RHIBs and dinghies

- How to replace an inflatable boat valve

- How to service and/or fit a replacement diaphragm to the Alfons Haar type SF1 inflation valve

- How to service or repair the Leafield Marine A7 or B7 inflatable boat valve

- How to service or repair the Leafield Marine C7 inflatable boat valve

- How to clean your RIB with August Race products

- How to winterise and store inboard engines and outboard engines

- How to make an emergency repair using TEAR-AID® Type A to a Hypalon inflatable boat, RIB, raft and other Hypalon / rubber inflatable structures

- How to make an emergency repair using TEAR-AID® Type B to a PVC inflatable boat, RIB, raft and other PVC / vinyl structures

- How to check your lifejacket

- How to install a TRIB airCap HR

- How to install a TRIB airCap LF for Leafield Marine C7 & D7 valves

- How to store your inflatable boat over winter

- How to look after and maintain the ropes on your boat

RIBs & Inflatable Boats

Safety Data Sheets

Blog

How to undertake a professional quality repair of your PVC or Hypalon RIB, inflatable boat and SIB tubes

Safety first

Adhesives and solvents produce fumes which can be damaging to your health when inhaled, absorbed through the skin/eyes or ingested. The fumes are also highly flammable. Always read the product labels carefully before starting the repair job.

The work area

Successful repairs to RIB collars and inflatable boat tubes are dependent upon the environment in which the repair is carried out - ideal conditions are:

- relative humidity less than 60% (low cost humidity meters can be obtained from most good DIY stores if unsure)

- temperature between 18°C and 25°C

- dry, shaded but well-ventilated work area

- no naked flames or uncovered heat sources in the vicinity

Identify the fabric type

Before contemplating your tube repair and buying adhesive or a repair kit, you will need to identify the inflatable tube fabric that your boat is made from. The type of fabric determines the type of adhesive, solvent and patch fabric that is required to undertake the repair.

Read: How to identify the fabric of your RIB or Inflatable Boat

Materials & tools required to complete this job

Tube repairs can be divided into small tears or punctures and larger tears (over 50mm long). Small tears/punctures can be repaired with a single patch to the outside of the tube, larger tears must be repaired by affixing a patch both inside and on the outside of the tube.

- 2-pack adhesive glue, such as ToobBond Hypalon 2-Part Adhesive Glue or PVC 2-Part Adhesive Glue

- Correct fabric patch (2 x patches if the tear is greater than 50mm long).

- Piece of polythene (if tear is greater than 50mm long. Cut to same size as inner patch)

- Solvent/primer e.g. MEK Solvent Cleaner for PVC or Hypalon Solvent Cleaner or acetone

- Sandpaper

- Mixing stick e.g. lollipop stick or epoxy mix stick

- Clean, lint-free cloth

- Short/stiff paint or glue brush

- Removable marker pen or pencil

- Masking tape

- Seam roller or rounded object e.g. screwdriver handle (to remove air bubbles)

- Heavy weight (to hold patch in-place whilst curing)

Materials & Tools

Get to work repairing the leaking tube

Locate the tear or hole on the tube. If unsure as to where the puncture is located, e.g. you have a ‘slow puncture’, then apply soapy water to the inflated tube and observe any bubbles forming at the puncture. Mark the location, dry the area and deflate the tube.

Bubbles identifying leak

Cut a fabric patch (two if the tear is greater than 50mm) with rounded corners, allowing a minimum 5cm overlap around the hole/tear. Place the patch over the hole and mark around the patch on the tube with a pencil/removable marker. If tear is greater than 50mm long then also cut one matching shaped piece of polythene.

Outline of patch being marked on the tube

For Hypalon patches only - Abrade the back of the patch, together with the marked repair area on the tube with abrasive paper to achieve a 'key' for the adhesive. Do not over-abrade as this could damage the fabric (there is no need to abrade PVC fabric).

Hypalon ONLY – Abrading the repair area and back of the Hypalon fabric repair patch

Clean/prime the back of the patch and the repair area, using a clean dry lint-free cloth, by wiping with MEK solvent or acetone. Wait until the solvent has evaporated. (N.B. with PVC fabrics, it is normal for the area to become 'tacky').

Clean and prime the repair area prior to applying the adhesive

Mask around the repair area on the tube with removable masking tape to prevent unsightly adhesive ‘overspill’ when applying the adhesive. Allow a 2-3mm gap around the pencil/removable marker line to allow for some stretch in the patch when applied.

The repair area on tube being masked-up

Mix the adhesive as per the instructions supplied with the adhesive. If the tear is greater than 50mm then, using a brush, apply a thin, even coat of adhesive to the back of one of the patches and to the inner tube surface around the repair area. Leave to dry for at least 20 minutes, apply a second coat leaving it to dry for 2 minutes or until tacky. Place the piece of polythene over the applied adhesive on the patch so that the patch can be rolled-up into a cigar-shape without the adhesive sticking to itself.

Applying the 2-part mixed adhesive to the masked and primed repair area

Insert the rolled-up patch into the tube through the cut or tear in the tube. Unroll the patch inside the tube. Position over the tear and peel away the polythene to allow the two glued surfaces to meet (N.B. as adhesives are ‘contact’ adhesives then it is important to position the patch correctly as it will not be possible to re- position once in place). Smooth the patch firmly using a seam roller or rounded object (e.g. piece of shaped hardwood or screwdriver handle), working from the centre of the patch outwards to smooth out any air bubbles and ensure good contact.

Insert the rolled-up, polythene covered, repair patch into the tube through the tear or cut in the tube.

Using a brush applicator apply an even thin coat of adhesive to both the back of the external tube patch and the masked repair area. Leave to dry for at least 20 minutes. Apply a second coat leaving it to dry for 2 minutes or until tacky. Apply the patch carefully to the repair area. (N.B. as adhesives are ‘contact’ adhesives then it is important to position the patch correctly as it will not be possible to re-position once in place).

Applying the 2-part mixed adhesive to the back of the repair patch

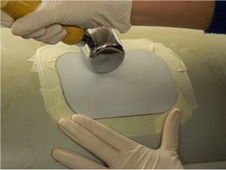

Smooth down the patch firmly using a seam roller or rounded object (e.g. piece of shaped hardwood or screwdriver handle), working from the centre of the patch outwards, in order to remove air bubbles and ensure good contact.

Smoothing the patch with a seam roller to expel air bubbles and ensure a good bond

If the patch is not sticking in places or air bubbles remain then the area can be gently heated with a hot-air gun or hair drier and ‘re- worked’ [Warning: do not use a hot-air gun or hair drier with adhesives or solvents still in the work area]

Remove the masking tape and clean-off any excess adhesive with the MEK solvent. It is important to remove any excess adhesive as if this remains on the surface of your tubes it will turn an unsightly brown!

Cleaning all excess glue from the repaired area

Place a smooth sided heavy weight on the patch and allow to 'cure' for 24 hours before re- inflating the tubes to check that the repair has been successful and before re-launching the boat.

View the RIBstore range of repair kits HERE

Did you know that RIBstore's owner, Samantha Tilley, comes from a RIB tube building, fitting and repairing background?

View & Download a PDF Version of this Guide How To Repair RIB & inflatable boat tubes by RIBstore